is there a list or a rough idea of what to set the speed to cut for the size of material we are cutting? I know each plasma machine is diff but a rough idea would help me alot, i am cutting 1/4 and the factory speed (1600) is way to fast

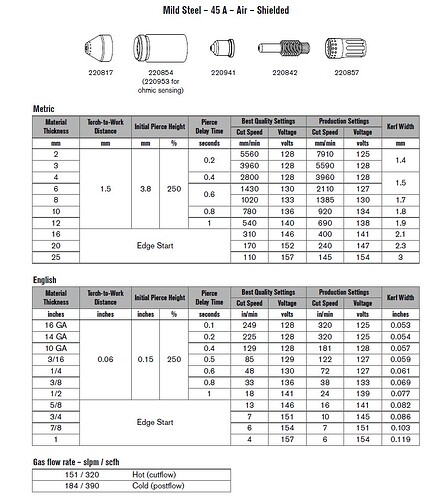

For 1/4” mild steel I would start here.

45 amps

.08” torch cut height

.2” pierce height

.5 sec pierce delay

60”/min cut speed

30A

.08” pierce z

.06” cut z

.75 Prc Delay

28” feed

Miller 375 Spectrum X-treme

What amperage are you wanting to cut at?

You can cut 1/4 mild steel anywhere from 40-100 amps.

For the best cut I like to run the lowest amperage and slowest speed possible.

For 1/4” I generally cut @ 40 amps - 45-50 ipm. .062 cut height about 1 second pierce delay ( depending on machine and nozzle size I usually set air pressure from 80-90 psi )

Just google plasma cnc setup chart for your specific brand and model of cutter, you will get a bunch of charts- if theres not one for your machine you can use a close comparison machine… ![]()

I guess Trevor didn’t like any of our answers……. Not a peep in the eleven days since his post for help.

im sorry had some personal issues to take care of i app all the answers thank yall