Was super excited to get setup with this machine but I’ve had nothing but issue after issue with it since I got it. Worked over two months with one file just trying to get it small enough to even load on the Arcdroid. I finally found where you can break the design up in to multiple files and cut one section at a time which started out good. But now taking the risk and cutting the files, the zero was shifted automatically from file one to file two and it offset the design. Tried to load the third file just to see the image so I could make any needed adjustments to the file since the metal is already wasted but at this point the zero completely disappeared and it wont let me load the file until I re-zero it, even though the zero button is highlighted. I was absolutely sure to make sure every file was saved at the precise location they needed to be so layout would be 100%. I’ve also been having x and or y servo overheating alerts even after finishing a small design without much detail. @Andrew could you weigh in on this please…

I also noticed a lot of chattering going on when I did the final cut. It was a large oval 24" x 14.4" and along the left most portion of the cut the arm was chattering and shaking around. The individual cut looks to be ok but it was disturbing seeing a fairly new machine that has hardly been used do this chattering.

-Was the file you were trying to load a DXF? if so try converting it to G code with fusion as this file type is more condensed.

-try running the ARCDROID without your torch attached and see if it still chatters, it could be from your torch lead getting caught.

-If it still chatters without a torch check your belt tension, there is a how to video on youtube.

-Last thing you could do is adjust the “Jerk” and “acceleration” settings, there is an old post about this on the here.

-I cant help you with the overheating error.

Run some of your cut files without the plasma torch connected to the arm. See if the torch induced loads are causing your overheating faults. It sounds to me that a few of your problems could be the torch physical setup.

Maybe a pic of your droid/table setup will help show something.

I’ll take a pic of my setup in a bit and load it a little later. I do have the torch cables suspended from the ceiling so there is no excess weight or interference form the cables. Have not had this chattering issue until the overheat errors appeared.

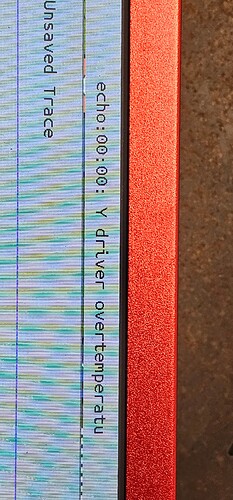

And just got this error when dry running the pattern to recreate the chattering. Error hit before the file finished.

I believe that Z error is from not enough slack in your torch cable from the roof. it needs to be very loose or it can pick up the Z axis and cause problems

I’ll double check it but I’ve always checked the slack in the cables before running a cut for too much and too little. There may be a chance I skipped that when just running a dry run.

I checked it and it happened the first time where the cable had the most slack and I checked the full range of motion of the arm and there was no strain on the cables at any time. They maintained efficient slack in all areas.

That is a lot of cable hanging. I can really see that causing problems.

Did you try running with the torch sled removed? Remove it from the equation…. You’ll need to touch off on a wooden block or lift the cable housing at the droid base unit to satisfy touching off.

It also looks like you are operating near the extreme of the -Z travel.

Remounting the faceplate of the head can get you closer to the work.

The weight of the cable is on the ceiling hook and not the torch. I tried doing a dry run but haven’t had the chattering thing happen again. I am still getting x overheating error though. Haven’t looked into belt tensions yet.

I did move the cable and zip tied it to the back of the handle so the cable isn’t anywhere near the z axis area. It does seem to respond better and guarentees no interference in that area. Double checked the full range of motion and there is no dragging the cable nor it getting any tension on it from any angle.

Machine has been siiting idle for awhile and nothing has moved to heat anything up. I just noticed that when I click Load, the Keep working or clear box pops up. Thats when the overtempature alert beeps and flashes on screen every time.

I have the z axis set to roughly mid range for 12 gauge plate. If I move the torch lower on the unit, it becomes too low to complete the calibration. And yes the files are DXF. I use Inkscape. I have Fusion 360 on my orher laptop but cant figure out how to do anything with it other than load the file I’m focusing on. And Fusion 360 doesn’t give the option for DXF unless purchased if I remember correctly. I did see something about Gcode on Inkscape but I have no clue what that does.

The alignment of slices of jobs is the biggest let-down on Arcdroid to me. If you happen to be running oversized work that will fit on the X2 great, you can throw money at it and fix the issue. But if you don’t have room to leave that set up, or you’re working on bigger pieces than the X2?

Best I’ve come up with so far is to put a fiducial feature (just a short line segment) at each of two common corner between each segment of the job. Then at least you can align the origin to one corner for positioning and use the other corner to align the rotation by using the pointer and going back and forth until they’re both on the axis.

I suspect it’s your cut file. You probably have a bunch of garbage that the machine is trying to deal with. i.e. lots of line segments to create arcs and “rough” transistions. I would be happy to look at your file. I’m sure others on here would look at it as well

I was very detailed in making sure my files were saved in the precise location and double checked it on the ArcDroid before cutting. It was a weird screen flash that happened when loading cut file two and that’s when the zero shifted two inches to the right. I learned to set my first zero, mark it with a pen and then re-zero between each file to that same location. Out of metal though so got to wait until I can pick up some more to test it out.

@wildman I would love to get some help on this file. I’ve been working with it for over two months and the only place Ive been able to get is making it into 4 different cut files. Its a gift for my Grandmother in her 90’s so its a pretty special piece.

send it to wildmanracing@aol.com …would love to help.